If we go back to PMBoK basics, the definition in the 5th edition is is:

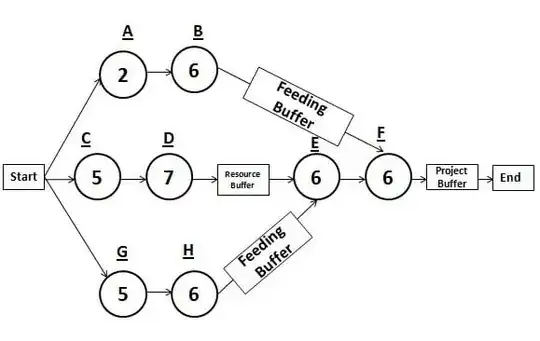

Critical Chain Method: A schedule method that allows the project team

to place buffers on any project schedule path to account for limited

resources and project uncertainties.

vs.

Critical Path Method: A method to estimate the minimum project method duration and determine the amount of scheduling flexibility on

the logical on the logical network paths within the schedule module.

Critical Path uses durations that are assumed to be accurate. Any schedule flexibility you get from the result only occurs in WBS elements that are not critical. For an ultra simple example, if drywall delivery is scheduled to take one week but dry wall prep is two days, both of which need to be complete before drywall installation, there is three days of flexibility in the drywall prep step since the delivery is on the critical path.

Let's extend the ultra-simple example. In a Critical Chain situation, you've decided that you don't trust the estimates for the entire critical chain of drywall installation. You add two days at the end of drywall installation as a Feeding Buffer and push back the start date of your finish carpenters to minimize the impact of your dry wall team being slow.

Adding or subtracting buffers allows you "protect" the underlying critical chain. A good half-dozen construction specialties rely on slab, underfloor, and plumbing to be complete before they can start (electrical, drywall, HVAC, etc.). If you have buffers on each of these feeding critical path elements, you can balance the actual performance vs. the plan.