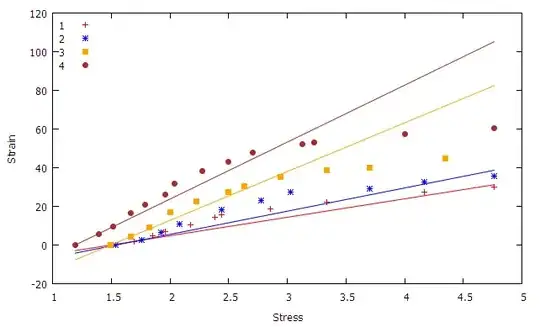

In the figure below, the stress-strain relationship is linear until they reach their corresponding plastic deformation points (A,B,C,D), beyond these points the relationship deviates from the linearity. The corresponding plastic deformation points shown in solid circles were actually determined by visual inspection (ball-parked). I am wondering if there is any better way to determine or quantify these points with any confidence level, say 90%.

(The above question is the second part of a previous question posted in this forum related to nonlinear fitting Here)

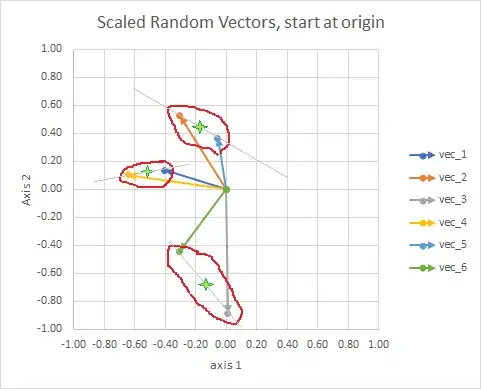

UPDATE: In the following first Figure, for each data set, I took first two points and fitted with a straight line. What was interesting that for each data set, the measured strain values were increasing on the left side of the linear fit and then gradually decreasing to the other side.

Then I took the difference between the measured and the predicted value, and plotted against the stress values as shown in the following figure. The points where the slopes changing are marked as in the figure in the original post.

But the same problem prevails,

- I had to chose the point based on my visual inspection

- Could not figure out how to choose confidence interval

- Not sure whether the procedure followed has any statistical significance

Any further comments would be highly appreciated.

Thanks!