I am trying to automate a problem I usually solve by hand.

I have a sensor that collects data from the field. Every 6 months or so, I have to do a calibration on that sensor by collecting x data points. Using a calibrated device, I measure the same data measured by the field sensor and I have the following table:

Field | Actual

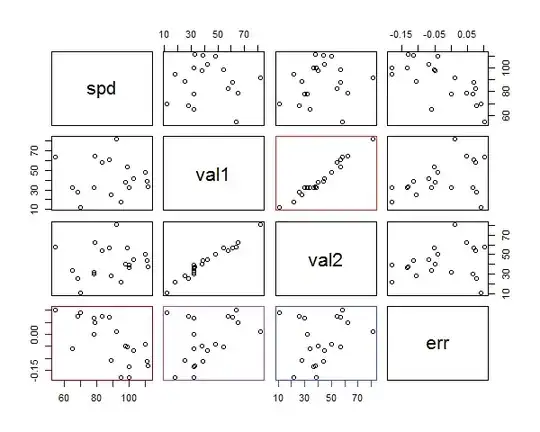

# spd val val err

1 89 25 28 -10.71%

2 100 32 39 -17.95%

3 54 64 58 10.34%

4 65 32 34 -5.88%

5 70 12 11 9.09%

6 100 32 37 -13.51%

7 110 48 50 -4.00%

8 78 32 32 0.00%

9 95 18 22 -18.18%

10 92 82 81 1.23%

11 78 32 30 6.67%

12 98 38 40 -5.00%

13 103 42 45 -6.67%

14 99 54 57 -5.26%

15 88 61 57 7.02%

16 79 65 62 4.84%

17 83 58 54 7.41%

18 111 39 44 -11.36%

19 112 33 38 -13.16%

20 68 28 26 7.69%

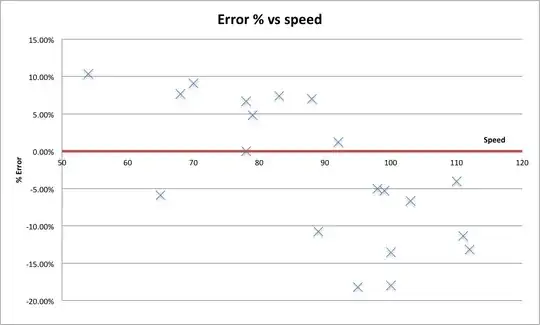

The following is the Error versus Speed plot:

How I currently solve this problem:

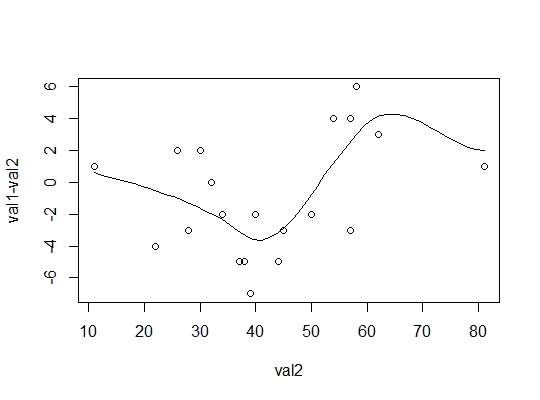

- look at the data visually and determine how the data is "trending".

- I can split the data in x bins (depending on how new the sensor is, newer sensors can divide in to multiple bins)

- For the example above, I notice 3 bins:

- 50 to 70 - around 10% with one outlier

- 70 to 95 - around 3-4% with one outlier

- 95 to 120 - around -10% with one outlier.

- I then create the three bins for the sensor

- based on these bins, I determine a

fudgeorcorrectionfactor for each bin - I then retest the sensor for more counts and redraw the graph. and repeat the process

- this process is time consuming especially when I have 10 sensors to look after, and that process can take up to 3 hours to complete

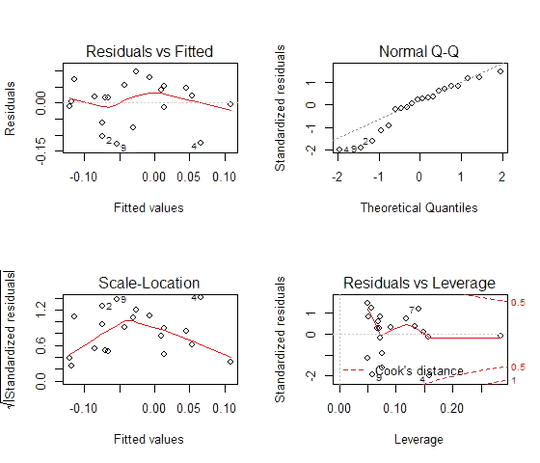

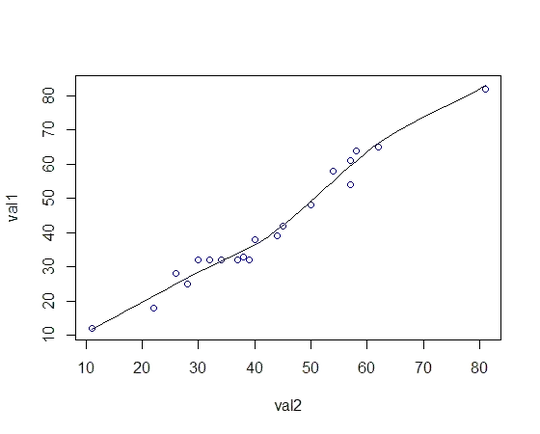

Question:

How can I create a statistical or mathematical solution to aid me in solving my problem?

Edit 1:

Some clarification:

- Speed: speed as the object hits the sensor

- Value: read by the sensor

- Final result is to obtain an average error of less than 6% on all reads

- Sometimes I collect more than 20 reads

- I would like to have uniformly calibrated across all ranges of speed as in the difference between actual vs measured to be relatively consistent so that every measured value could be used without significant error

Edit 2:

- tools I have access to are Excel, Python, and R (in that order of usability for myself)

Edit 3:

- Each object that's hitting the sensor is different in shape, size, and speed, so therefore the object hitting at any speed is not related to the size of the object. The sensor as it gets older tends to reads values differently at different speed bins.

Edit 4:

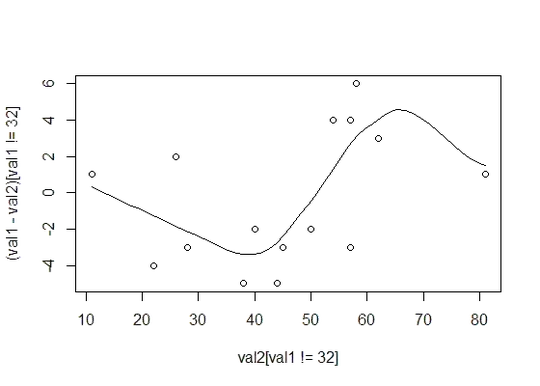

- Based on @Glen_b 's answer, I created the following MS Excel file for non binned results:

http://97.107.136.148/results_stats_se.xls. Disregard thesteercolumns in the excel sheet. as it does not impact this problem.

Edit 5:

- I collected more data as shown below.

- Sub is a partial measurement of the object, so sub is part of the full_measurement.

- There is no ratio relationship between sub and full other than it's sub

Data:

Speed Non Calibrated sensor Calibrated sensor

Speed Sub_1 Measurement_full Sub_1 Measurement_full

sensor 1

88 5500 51800 5610 49010

95 5400 66000 5630 62700

sensor 2

99 4700 34600 43100 35850

103 5400 38200 5160 35360

84 4900 47700 4550 48330

101 5400 44800 5190 43050

106 5200 28400 5290 24390

96 4900 44900 4730 42900

104 5300 35000 5350 35290

102 5400 47700 5290 46810

99 5500 35500 5270 34410

89 5400 35600 5290 35490

98 5300 39300 5240 37580

sensor 3

93 5000 35600 4860 31050

79 5500 41000 5130 37810

92 4600 30700 4750 29720

99 4900 47100 4820 46230

94 5100 48300 4990 48230

93 5300 51600 5460 54850

99 5100 41700 4910 38960

85 5100 42200 4960 42810

81 5500 44100 5120 37960

98 5600 64300 5550 62510

102 5300 33400 5380 31220

sensor 4

106 4800 35000 4430 30440

99 5900 56300 5590 52740

78 5900 56300 5730 54380

96 6300 49100 5620 47790

98 5500 42100 5340 38340

70 5300 45700 4750 43670

77 5100 37900 5100 34470

106 4300 12100 3930 9750

107 5800 35600 5270 28930

90 3800 32300 3310 29390

75 5800 62200 5490 61470

88 4900 39200 5010 35720

sensor 5

104 4500 44200 5000 45120

95 5460 49400 5440 48520

104 4700 33900 5210 33420

86 5200 36400 5280 35140

88 5000 49500 5760 52250

94 5300 44400 5200 43310

95 5200 54000 5370 54460

99 5100 37000 5410 35600

91 5600 62400 5540 61860

95 5400 38000 5310 32510

94 5100 49300 4990 46210

101 4800 44300 5380 45130

100 6600 23700 7500 24630

105 5100 29200 5400 26740

94 5500 42400 5730 40760

89 5200 49600 5270 49570

99 5300 47100 5700 47970

100 4900 36600 5220 36790

90 7200 25500 7340 23480

100 5200 36500 5410 36210