I am responsible for a large electricity meter fleet and would like to compare and predict the failures of different types electricity meters from existing data. We have the current number of meters installed and the installation dates. We also have the failure and removal database that includes the installation and removal dates.

The number of meters installed of each type does not remain constant, as can be imagined with more than 20 years of data. When meters fail, they are immediately replaced by either the same or a similar model.

I have found that using quarterly data makes the data more manageable but the raw data remains available for analysis.

From the failure database the number of failures vs. time gives meaningful data until about half the population have failed. How do I normalise this? Do I divide the failures with the number of meters remaining, or do I use another metric?

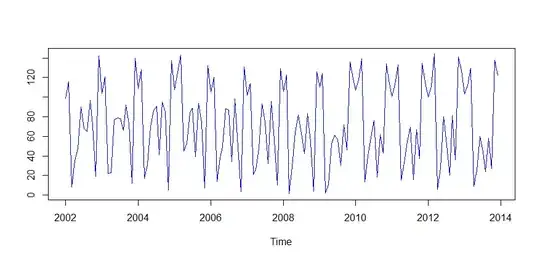

I have also plotted Duane Plots from the detail data, the cumulative failures $F_i = \sum f_i$ divided by $T_i = \sum N_i \cdot t_i$ vs. $T_i$. This provides some meaningful statistics for some types of meters but not for others. I attach a sample graph below.

Is there any other analysis I should use? The focus is to identify the onset of the wear-out for pro-active replacements.

Further, from renewal theory the total replacement cost is the sum of the failure replacement cost $C_f$ and planned block replacement cost $C_p$ as folows:

$$c(t) = \frac{H(t)\cdot C_f+ N\cdot C_p}{t}$$

The minimum is:

$$0 =\frac{dc(t)}{dt}$$

giving

$$t\frac{dH(t)}{dt}-H(t) = N\frac{C_p}{C_f}$$

or

$$t\frac{\Delta H(t)}{\Delta t}-H(t) = N\frac{C_p}{C_f}.$$

I suspect that in my case I also have $N(t)$ and therefore the equation is:

$$t\frac{\Delta H(t)}{\Delta t}-H(t) = \frac{C_p}{C_f}\left(N(t)-t\frac{\Delta N(t)}{\Delta t}\right).$$