I'm working with a vacuum chamber. I have one test per day in which we test if the chamber's seals are still good enough for operation. In each test I have measurements every 60 seconds for 5 minutes (0, 60, 120, 180, 240, 300 seconds). I know that if the vacuum difference between one measurement and the prior one is bigger than 0.04 the test fails.

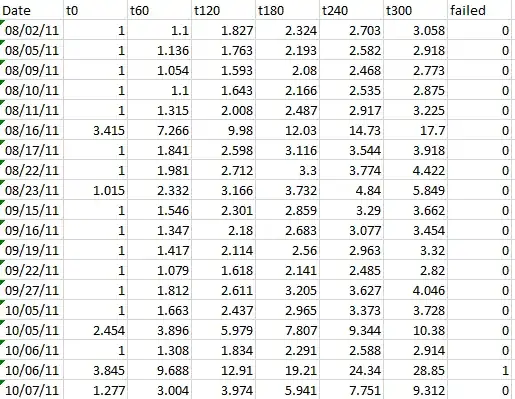

This would be a compact dataset: if the last column is a 0 the test went OK. If it is a 1 the test failed.

My goal is to determine when the machine will fail the test, so that the technical team can do some predictive maintenance before the machine breaks down. I started working with survival analysis in R to try to get somewhere, but I'm getting confused since the result of the test (failed or OK) depends on the relation between measurements on that same test.

What would be the best approach for this?